| Steyr

Puch incorporated a

drive shaft "decoupler" into its design of the

syncro, which allowed the driver to engage and disengage power

to the

front differential. With a few exceptions, it never made it into

production.

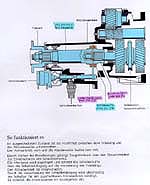

The

basic design and parts are depicted in ETKA, although only some of them

are available from VW. The critical parts are not

available.

The reason that the decoupler never made it into production appears to

be that it was designed primarily for the few very early production

syncros

that did not have a viscous coupling. On those syncros, the drive

shaft needed to be disconnected when four wheel drive was not being

used

or was not needed in order to reduce stress on the transmission and

improve

drivability on paved roads.

The

incorporation of a viscous coupling rendered the decoupler

redundant. The

VC

acts as an automatic decoupler or disengager. In theory, it

transmits

power to the

front wheels only when there is a differential in speed between the

front

and rear wheels. If there is no slippage or differential in

speed,

the main drive shaft is in effect disconnected from the front wheels

since

the VC is spinning freely and not transmitting any power. Thus

there

is, in theory at least, no need for a drive shaft decoupler.

In

reality, however, the VC

does

not function flawlessly under all driving conditions. Even on

straight

freeway, the VC transmits some torque to the front differential.

On twisty roads, the VC gets a good workout and in turn transmits

additional

stresses to the entire drive train. And if the VC is on the

aggressive

side, or is aging, it can engage on hot days after high speed traveling

to an extent that does cause wind up in the drive train, and hence

undue strain on the components. For this reason, many believe

that a

decoupler

saves wear and tear on the drive train (particularly during

high-speed freeway driving in hot temperatures) and thus prolongs

its life.

Others claim that the decoupler does not save on wear

and tear, and note that the benefits of AWD are lost with it.

|

|

If

the VC is removed and a straight shaft is put in its place, a decoupler

becomes essential. This converts the syncro back to the pre-VC

early

production stages. Why would anyone do that? At Syncro de

Mayo this

year, a couple of vans had the straight shaft-decoupler set up.

It was

obvious to the casual observer that

the straight shaft syncros out-performed the VC equipped syncros in the

toughest off-road conditions.

The syncros with VCs were not as sure-footed and not as smooth over the

really rough and steep terrain. While it appears, therefore, that

a

straight-shaft - decoupler combo is a sure thing when it comes to

enhancing the syncro's off-road 4WD performance,

the straight shaft precludes use

of 4WD on paved roads, except on

snowy and slick roads that allow some wheel slippage.

Decouplers

are available from enterprising inventors in South Africa, Germany and

the US. There are two designs. The South African and German

designs

are depicted in the photo on the left below and track the VW design

depicted in the drawing, above. The US design uses a different

approach for mating two shafts together, but otherwise

functions the same. The South African kit required assembly

and also machining of the nosecone casing to accept the actuator rod,

the switch and mounting plate, which is a job that requires machine

tools. The German and US kits come pre-assembled.

Installation

takes about 4 hours and is not a complex job, nor does it require

special tools (see photos linked below).

South African & German Design

|

US design

|

South African Decoupler Kit

|

US

Decoupler Kit

|

Decoupler

Installation Photo Decoupler

Installation Photo |